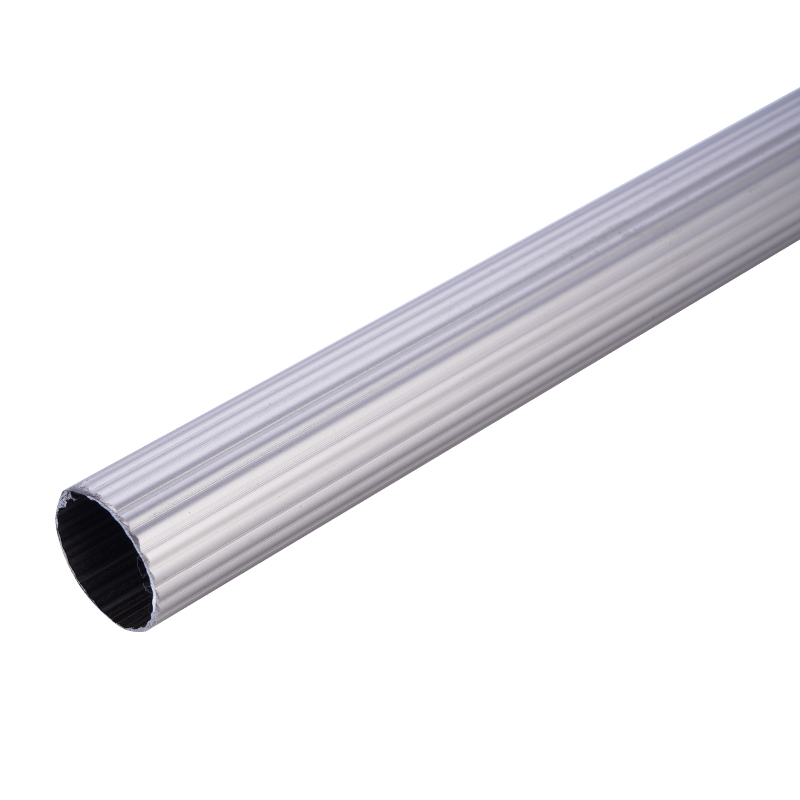

Twisted Curtain Tube is a kind of tube that is becoming more and more popular in curtain installation. Its special twisting design brings unique aesthetic effect and greatly enhances the strength of the tube. Compared with traditional round or square curtain rods, twisted curtain tubes have higher structural stability and load-bearing capacity. So, what makes twisted curtain tubes so strong?

1. Twisted design is essentially an optimization of geometric shape. Through the twisted or spiral tube body, the curtain tube can more effectively disperse and resist the external force. Compared with traditional straight rods, twisted tubes can better maintain the uniformity of deformation when subjected to force and reduce the concentration of local stress. Local stress concentration is often the main cause of deformation or fracture of the rod body, and the twisting design can make the entire tube more stable and durable by distributing these stresses more widely.

In mechanics, twisted structures can usually improve the torsional stiffness of an object, that is, the ability of an object to resist twisting. This means that twisted curtain tubes can better maintain their shape when subjected to lateral pressure. For example, when hanging heavier curtains, the rod body will not bend or deform easily when subjected to gravity, which makes the curtain rod more durable in long-term use.

2. The twisted design also effectively increases the surface area of the curtain tube. With the same amount of material, the surface area of the twisted tube is larger than that of ordinary round or square tubes. This increased surface area can effectively improve the compressive strength and tensile properties of the tube. When external force acts on the tube body, the twisted shape makes the force more evenly distributed throughout the tube body, rather than concentrated in one place, avoiding the appearance of structural weak points.

The twisted structure also makes the cross-sectional shape of the tube more complex. This complexity increases the moment of inertia of the material. The greater the moment of inertia, the stronger the material's ability to resist bending and torsion. For curtain rods that need to withstand greater weight and tension, the increase in moment of inertia greatly improves the overall strength of the rod body.

3. The high strength of the twisted curtain tube comes from its unique design, and is also inseparable from the materials and processing technology used. Usually, this curtain tube is made of high-strength materials such as aluminum alloy, stainless steel or iron. These metal materials themselves have good tensile, compressive and torsion resistance, which can effectively improve the strength of curtain rods.

The production process of twisted curtain tubes is also very critical. Through high-precision processing technology, the twisted shape of the tube can be accurately formed to ensure that the mechanical properties of each section of the tube are consistent. High-temperature heat treatment process can further enhance the strength of metal materials, making them less likely to break or deform during use. At the same time, surface treatment such as electroplating or spraying can prevent the tube from rusting and improve its durability and aesthetics.

4. Twisted curtain tubes perform well when carrying weight, and their deformation resistance is far good to traditional curtain rods. During long-term use, curtain rods will bend or twist due to the pulling of curtains, gravity and other external forces. Ordinary straight rods are prone to permanent deformation due to uneven force after long-term use. The twisted curtain tube has a natural deformation resistance due to its spiral design, and can remain in its original shape after long-term force.

This deformation resistance comes from the effective dispersion of force by the spiral shape. Each spiral part of the spiral pipe can transfer pressure to other surrounding parts when subjected to force, thereby preventing a certain part from being overstressed and causing deformation.