Determining the appropriate weight load for curtain rod connectors is crucial to ensure the curtain rods remain stable and do not sag or warp over time.

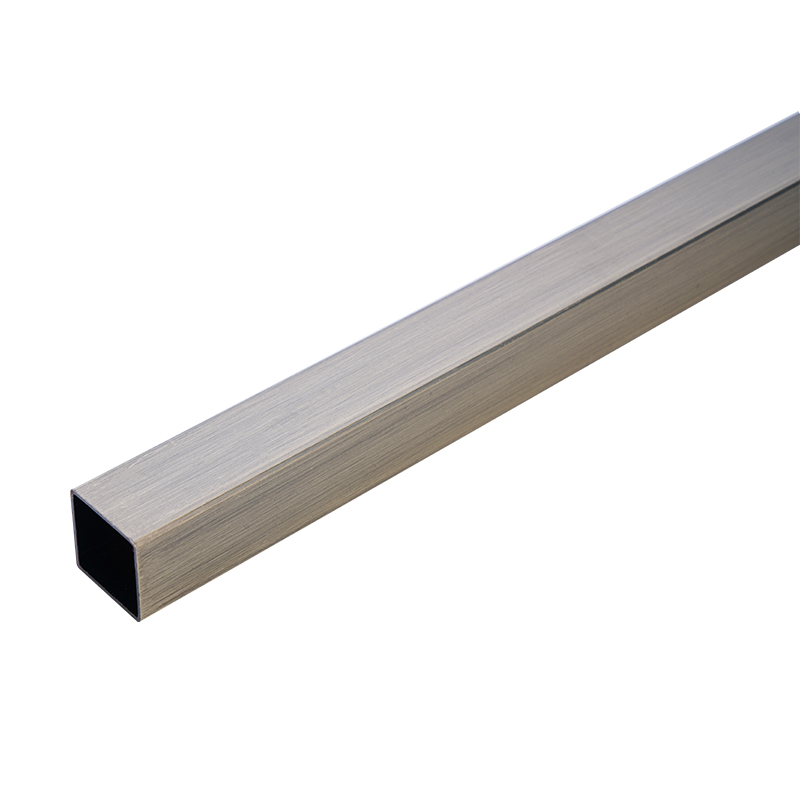

Metal vs. plastic connectors: Metal curtain rod connectors (e.g., steel, aluminum) generally have a higher weight tolerance than plastic connectors, which may be more prone to breaking or warping under heavy loads.

Reinforced connectors: Choose connectors with added reinforcements or a more robust design (e.g., thicker walls, cross-bracing, or additional locking mechanisms) for heavier curtains. Look for connectors that explicitly state their weight-bearing capacity in the product details.

Larger rods can support more weight: Thicker, sturdier rods, typically with a larger diameter (1.5 inches or more), are better equipped to handle heavier curtains. If your curtain rod is on the thinner side, you may need a connector with a higher weight capacity to prevent sagging.

Rod material: The material of the curtain rod itself (e.g., wood, steel, or aluminum) also affects its weight-bearing capacity. Ensure that the rod’s strength matches the weight of the curtains and the connectors.

Bracket placement: Brackets should be placed evenly along the length of the curtain rod to distribute the weight of the curtains. For longer curtain rods, additional middle brackets or center supports may be needed to prevent sagging and to distribute the weight load more evenly.

Reinforced brackets: Choose heavy-duty brackets designed to hold more weight if you plan to hang heavier curtains. Some curtain rods and connectors are designed to work together with reinforced brackets for better stability.

Longer rods require more support: Longer curtain rods are more prone to sagging under weight, especially in the center. When using a longer rod, additional supports or middle connectors should be added to prevent excessive bending or warping.

Consider the stacking weight: If you are using connectors to extend the rod, ensure the extension is securely supported. Extended rods are typically more vulnerable to sagging, so the connectors and supports must be strong enough for both the length and the weight.

Frequent use: If you open and close your curtains often, the load on the connectors will fluctuate. Choose connectors that can handle dynamic stresses as well as static weight. Over time, frequent movement can cause connectors to weaken, especially if they are under constant strain.

Weight distribution: Make sure the curtains are evenly distributed across the rod. Lopsided weight distribution can create additional stress on connectors, causing sagging or even breaking over time.

Durability over time: Look for connectors that are built for long-term use and have been tested for strength and durability. High-quality connectors made from materials like steel, aluminum, or reinforced plastic are better equipped to handle larger loads without warping or bending.

After installation, periodically check the condition of the curtain rod connectors and the overall setup. If you notice any sagging or shifting, this could be a sign that the connectors or the rod are overloaded, and adjustments may be needed (e.g., adding more brackets or switching to stronger connectors).

To determine the appropriate weight load for curtain rod connectors and avoid sagging or warping, carefully consider the total weight of the curtains, the weight rating of the connectors, the rod material and thickness, and the type of support structure you use. Always match the strength of the connectors with the curtain rod and choose connectors rated for the weight of your curtains, ensuring even weight distribution and proper bracket support for optimal performance.