Advantages of Zinc Alloy Curtain Hooks Using Zinc Alloy

1. Excellent durability and strength

Zinc alloy curtain hooks are known for their excellent durability and strength. Zinc alloy is an alloy made by mixing zinc with other metal elements (such as copper, aluminum, etc.) in a certain proportion. This alloy has high strength and hardness, which enables curtain hooks to withstand greater tension and weight. Whether it is heavy curtains or frequent pulling and closing operations, zinc alloy curtain hooks can maintain stable performance and ensure the safe use of curtains.

2. Excellent corrosion resistance

Another significant advantage of zinc alloy curtain hooks is its excellent corrosion resistance. Because zinc alloy contains a certain amount of zinc, this element can form a dense oxide protective film in the air, which effectively prevents erosion from the external environment. Therefore, zinc alloy curtain hooks can resist adverse factors such as moisture, oxidation and corrosion, and maintain long-lasting luster and beauty.

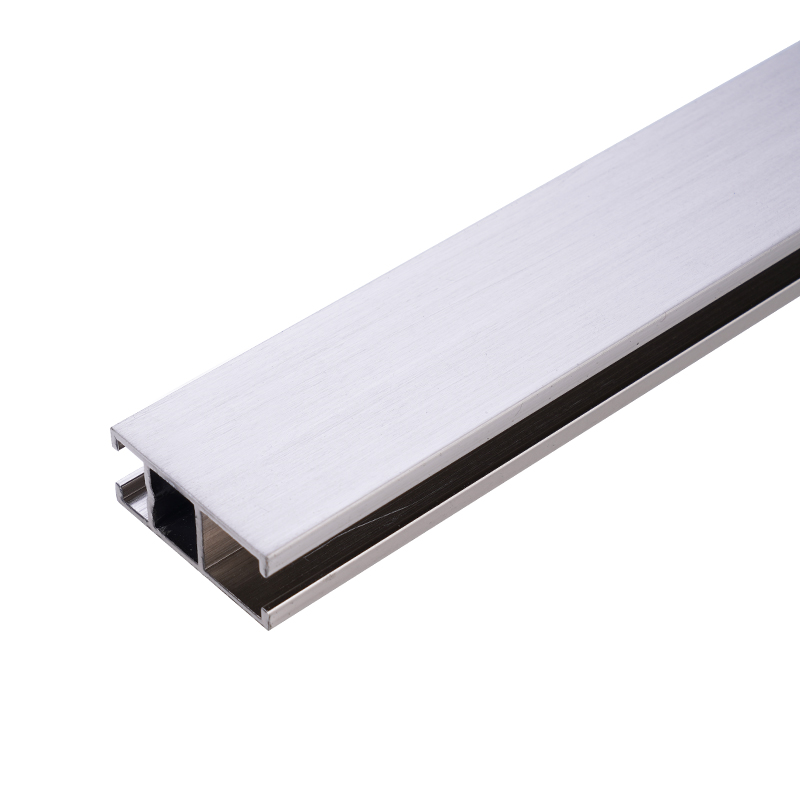

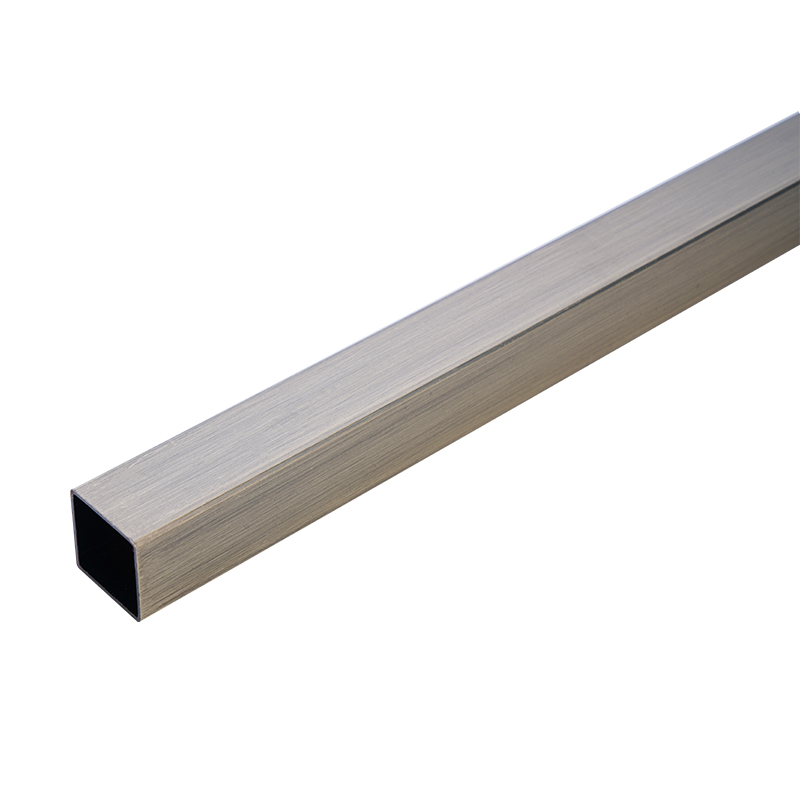

3. Rich colors and shapes

Zinc alloy curtain hooks have a wealth of choices in color and shape. Zinc alloy materials can present various colors and textures through various surface treatment processes such as electroplating and spraying to meet the aesthetic needs of different consumers. At the same time, zinc alloy materials also have good plasticity and processing properties, and can be processed into curtain hooks of various shapes and specifications, providing more diversified choices for home decoration.

4. Environmental protection and pollution-free

In modern society, environmental protection has become the focus of people's attention. As an environmentally friendly material, the production process of zinc alloy curtain hooks is pollution-free and non-toxic, and will not have a negative impact on the environment. At the same time, zinc alloy materials can be recycled and reused, which is in line with the concept of sustainable development. Therefore, choosing zinc alloy curtain hooks is not only for beauty and practicality, but also a contribution to environmental protection.

5. Easy installation and convenient maintenance

The installation process of zinc alloy curtain hooks is relatively simple, without complex tools and skills. Users only need to follow the instructions or the guidance of professionals to easily complete the installation. The maintenance of zinc alloy curtain hooks is also very convenient. Because of its smooth surface and not easy to accumulate dust, it only needs to be wiped with a soft cloth regularly to keep it clean. This simple installation and maintenance method makes zinc alloy curtain hooks more convenient and practical in actual applications.

6. Good cost performance

Zinc alloy curtain hooks not only have excellent performance and beautiful appearance, but also have good cost performance. Compared with curtain hooks made of other materials, zinc alloy curtain hooks are relatively moderate in price, stable in performance and long in service life. Therefore, choosing zinc alloy curtain hooks can not only meet the needs of consumers, but also save costs for consumers.

What is the die-casting process for making Zinc Alloy Curtain Hooks?

Die-casting is a crucial link in the manufacturing process of zinc alloy curtain hooks. It not only determines the basic shape and size of the hooks, but also directly affects the appearance quality and performance of the product. The preparation work before die-casting is the basis for ensuring the smooth progress of the whole process, which includes selecting suitable zinc alloy materials, preparing die-casting molds, adjusting die-casting machines, etc. The selection of zinc alloy materials should take into account its mechanical properties, corrosion resistance and machinability to ensure that the finished curtain hooks have excellent quality. The design and manufacture of die-casting molds are also crucial, which determines the shape and dimensional accuracy of the product.

1. Melting zinc alloy

Before die-casting, the zinc alloy material needs to be melted. This process is usually carried out in a special melting furnace, and the zinc alloy is heated to a molten state. During the melting process, the temperature and time need to be strictly controlled to ensure that the composition of the zinc alloy is uniform and free of impurities.

2. Preheating of die casting mold

In order to ensure that the zinc alloy can solidify quickly and reach the expected shape and size when injected into the mold, the die casting mold needs to be preheated. The preheating temperature is usually determined according to the type of zinc alloy and the performance of the die casting machine. The preheated mold can reduce the cooling rate of the zinc alloy in the mold, thereby improving the molding quality of the product.

3. Die casting

Die casting is the core step in the manufacture of zinc alloy curtain hooks. In this process, the molten zinc alloy is injected into the preheated die casting mold. Under the action of high pressure and cooling, the zinc alloy solidifies rapidly and fills the mold cavity to form the basic shape of the hook. The specific process of die casting includes the following steps.

Injection: The molten zinc alloy is injected into the mold cavity through the injection system of the die casting machine. The injection speed and pressure need to be precisely controlled to ensure that the zinc alloy can evenly fill the cavity.

Pressure holding: After the zinc alloy is injected into the mold, a certain pressure needs to be maintained to ensure that the zinc alloy is fully solidified in the mold and reaches the expected density and strength. The length of the pressure holding time depends on the type of zinc alloy and the design of the mold.

Cooling: During the pressure holding process, the zinc alloy gradually cools and solidifies in the mold. This process requires strict control of the cooling rate and temperature gradient to avoid defects such as deformation or cracks in the product.

Mold opening: When the zinc alloy is completely solidified and cooled to a certain temperature, the mold can be opened to take out the product. The mold opening process needs to be cautious to avoid damage to the product or mold.

4. Subsequent processing

The zinc alloy curtain hooks after die casting also need to be processed later, such as deburring, grinding, surface treatment, etc. These processing steps can further improve the appearance quality and performance of the product and increase the added value of the product.

5. Quality inspection

After die casting and subsequent processing, the zinc alloy curtain hooks need to be quality inspected. The inspection content includes appearance quality, dimensional accuracy, load-bearing capacity and other aspects. Only products that have passed strict inspection can enter the market.