Advantages of Traditional Curtain Bracket

1. Stability and durability

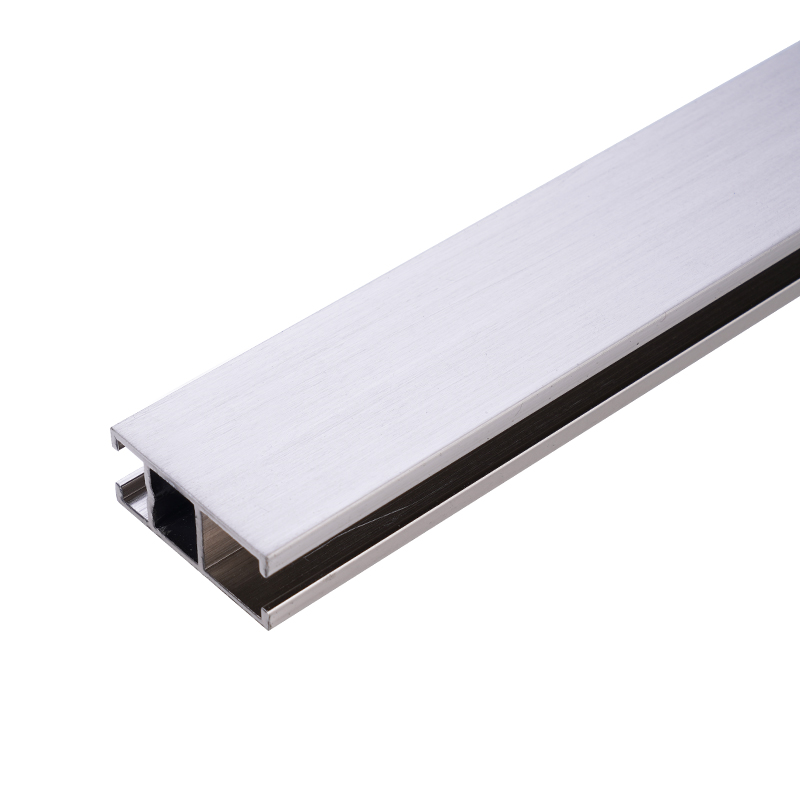

The primary feature of traditional curtain brackets is their excellent stability and durability. They are usually made of high-strength metal materials and are processed through precise processes to ensure the strength and durability of the brackets. Whether it is hanging heavy fabric curtains or light gauze curtains, traditional curtain brackets can provide stable and reliable support to ensure the safety and stability of the curtains during use. Its metal material also has good anti-rust and anti-corrosion properties, and can maintain a long service life in various environments.

2. Elegant appearance design

In terms of appearance design, traditional curtain brackets pursue an elegant and generous style. Its smooth lines and simple shape can be easily integrated into various home styles, adding elegance and nobility to the interior space. Whether it is a classical European home or a modern minimalist style, traditional curtain brackets can complement each other and show extraordinary taste and temperament. At the same time, the surface treatment process of traditional curtain brackets is also very particular. Usually, spraying, electroplating and other processes are used to make the surface of the bracket present a delicate and smooth texture, which further enhances its overall beauty.

3. Wide applicability

Traditional curtain brackets have a wide range of applicability and can meet the needs of different home environments and curtain types. Whether it is the size and shape of the window, or the material and weight of the curtain, the traditional curtain bracket can provide a suitable solution. Its diverse models and specifications make consumers more flexible and convenient when choosing. At the same time, the installation method of traditional curtain brackets is relatively simple, and the installation can be completed without complex tools and skills, which greatly saves installation costs and time.

4. Personalized customization service

With the increasing demand of consumers for personalized home decoration, traditional curtain brackets also provide personalized customization services. Consumers can choose curtain brackets of different materials, colors, and styles according to their preferences and needs, and even engrave their own names or special logos on the brackets to show their unique taste and personality. This personalized customization service not only meets the personalized needs of consumers, but also injects new vitality and creativity into traditional curtain brackets.

5. Environmental protection and sustainable development

Today, as the concept of environmental protection and sustainable development becomes more and more popular, traditional curtain brackets also actively respond to this trend. It is made of environmentally friendly materials, non-toxic and harmless, and harmless to both the human body and the environment. At the same time, the production process of traditional curtain brackets also focuses on energy conservation, emission reduction and resource recycling, which reflects the company's environmental awareness and sense of responsibility. This concept of environmental protection and sustainable development also makes traditional curtain brackets more competitive and attractive in the market.

What is the material processing process in the production process of Traditional Curtain Bracket?

In the production process of Traditional Curtain Bracket, material processing is a crucial link. It involves the transformation from raw materials to the final product form, and is the basis for ensuring that the curtain rod bracket is beautiful, durable and practical.

1. Material selection and preparation

Before material processing, the first thing to do is to select and prepare materials. For Traditional Curtain Bracket, common materials include metal (such as iron, copper, stainless steel, etc.), wood (such as mahogany, pine, etc.) and plastic or synthetic materials in a few cases. The choice of these materials depends on the design requirements, use environment and cost considerations of the product. When selecting materials, factors such as strength, corrosion resistance, aesthetics and processing performance need to be considered. Metal materials usually have higher strength and corrosion resistance, and are suitable for making curtain rod brackets with higher load-bearing and durability requirements; wood has natural beauty and warmth, and is suitable for making products that focus on decoration and environmental protection.

2. Processing process of metal materials

Cutting: Use cutting machines or sawing machines and other equipment to cut metal materials into the required length and shape according to the size requirements of the design drawings.

Punching: Use punching machines or drilling machines and other equipment to punch the required holes on the metal materials for subsequent assembly and connection.

Bending: For metal materials that need to be bent into specific shapes, pipe bender or bending machine can be used for processing.

Welding: Weld the cut, punched and bent metal materials to form a complete curtain rod bracket structure. The welding process needs to ensure that the weld is firm, flat and meets the design requirements.

Grinding and polishing: Grind and polish the welded metal materials to remove welding marks and burrs, and improve the beauty and finish of the product.

3. Processing process of wood

Drying: For newly cut wood, it needs to be dried first to remove moisture and moisture in the wood to prevent the product from deforming or cracking during use.

Cutting: Use sawing machines and other equipment to cut the wood into the required length and shape.

Polishing: Polish the cut wood to remove burrs and uneven parts on the surface, making the product smoother and more delicate.

Carving: If you need to increase the decorativeness of the product, you can carve on the wood. Carving can be done according to design requirements, which can be simple line carving or complex pattern carving.

Painting or dyeing: Paint or dye the polished and carved wood to protect the wood surface and increase the beauty and durability of the product. The color and effect of painting or dyeing can be customized according to customer needs.

4. Processing process of plastic or synthetic materials

For curtain rod brackets made of plastic or synthetic materials, the processing process usually includes injection molding, cutting, polishing and other steps. Injection molding is the process of injecting molten plastic into a mold and forming the desired shape after cooling; cutting and polishing are post-processing of the injection molded product to remove excess parts and improve the beauty and precision of the product.