Advantages and Applications of Curtain Wall Bracket

1. Advantages of Curtain Wall Bracket

Strong load-bearing capacity: The curtain wall bracket is made of high-quality materials and has been precisely designed and processed to ensure its strong load-bearing capacity. Whether it is heavy curtain fabrics or complex curtain systems, the curtain wall bracket can provide stable and reliable support to ensure the safe use of curtains.

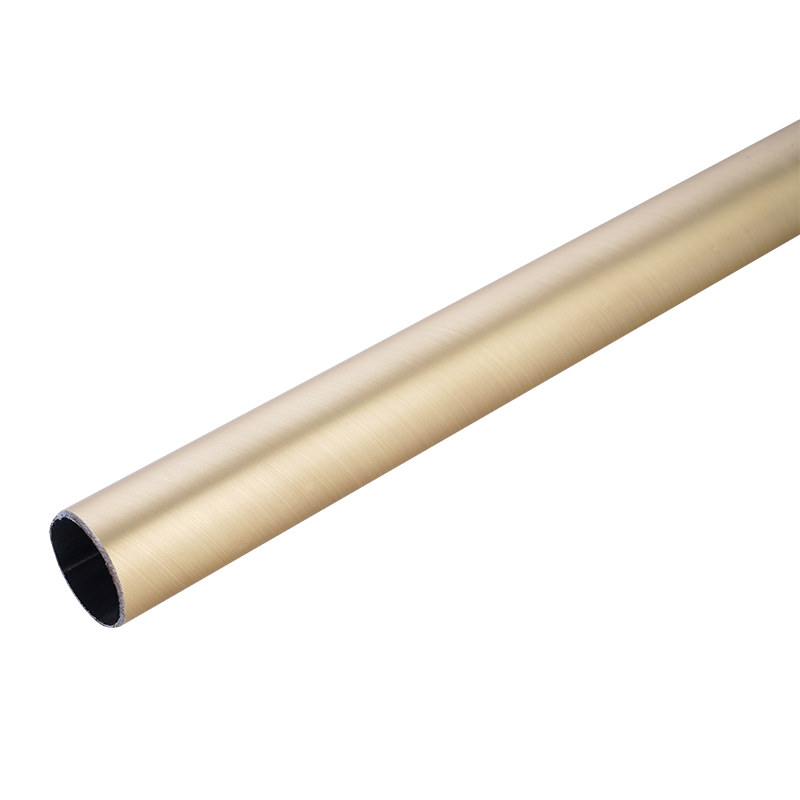

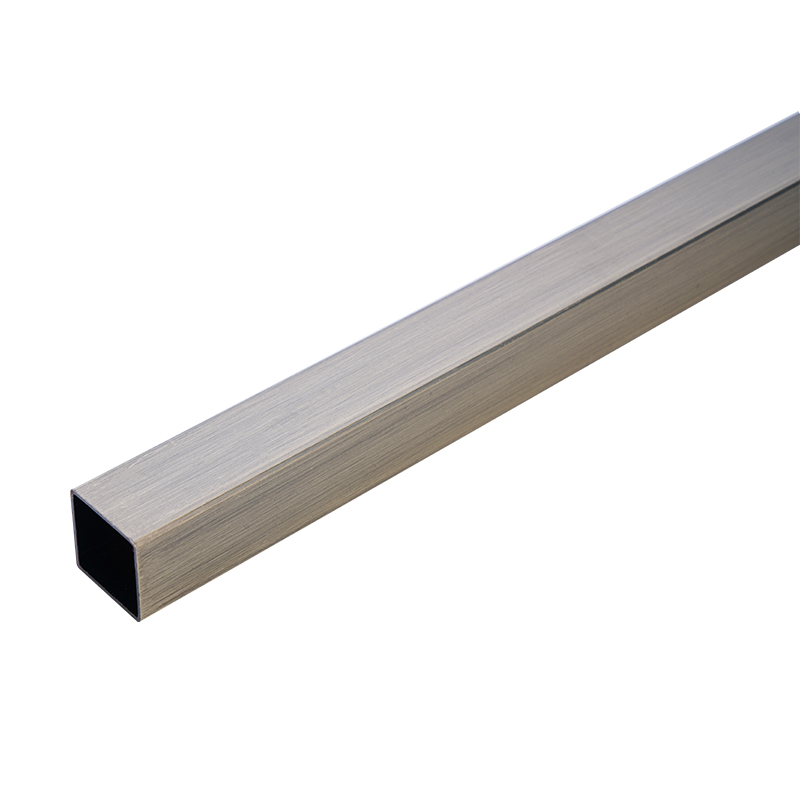

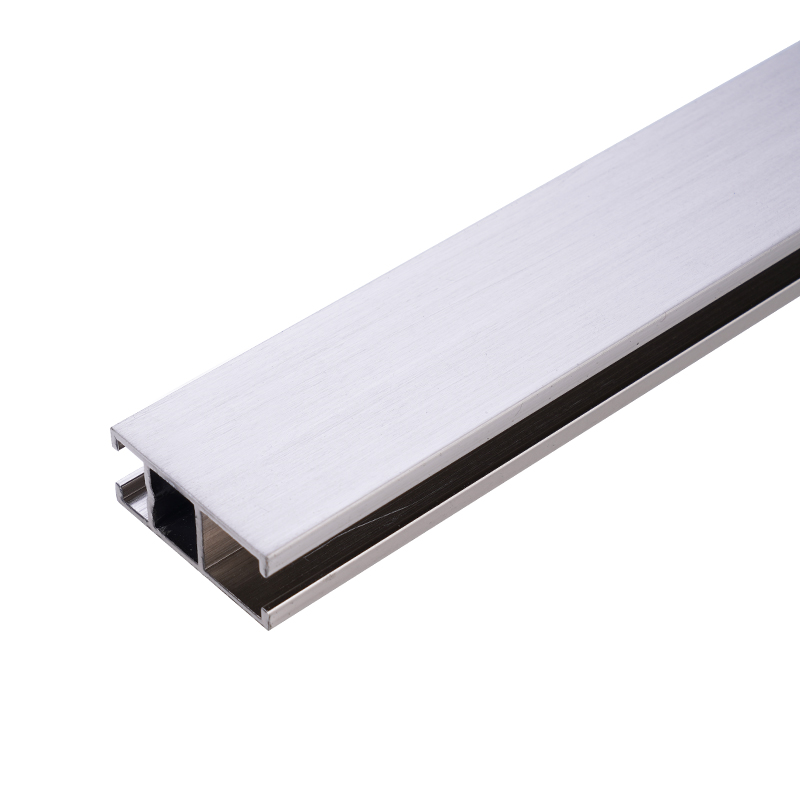

Beautiful appearance design: The curtain wall bracket focuses on the combination of beauty and practicality in appearance design. Its simple and elegant shape and smooth lines can be integrated with various architectural styles, adding elegance and sophistication to the building facade. At the same time, the choice of a variety of materials and colors also provides designers with more creative space, making the curtain wall bracket an important element to show the personality of the building.

Easy to install and maintain: The installation process of the curtain wall bracket is relatively simple, without the need for complex construction tools and skills, which greatly reduces the installation cost and time. At the same time, its structural design is reasonable, easy to disassemble and clean, making future maintenance work more convenient.

Strong adaptability: The curtain wall bracket has a wide range of adaptability and can adapt to curtains of different materials, weights and sizes. Whether it is traditional fabric curtains or modern smart curtain systems, the curtain wall bracket can provide a suitable support solution. In addition, curtain wall brackets can adapt to various climatic conditions and changes in the external environment, maintaining their stable performance and service life.

Energy saving and environmental protection: In modern buildings, energy saving and environmental protection have become important design concepts. Curtain wall brackets focus on energy saving and environmental protection in the design and manufacturing process, and use environmentally friendly materials and energy-saving technologies to reduce pollution and damage to the environment. At the same time, through reasonable design and use, curtain wall brackets can also effectively adjust indoor light and temperature and improve the energy efficiency of buildings.

2. Application of curtain wall brackets

Commercial buildings: In commercial buildings, curtain wall brackets are widely used in shopping malls, hotels, office buildings and other places. Its strong load-bearing capacity and beautiful appearance design enable commercial buildings to show a more professional and high-end image. At the same time, by reasonably adjusting the opening and closing degree of curtains, different atmospheres and styles can be created for commercial spaces.

Residential buildings: In residential buildings, curtain wall brackets are also widely used in bedrooms, living rooms and other places. By choosing suitable curtain wall brackets and curtains, you can add a sense of warmth and comfort to your home space. At the same time, the easy installation and maintenance of curtain wall brackets also make the decoration of home space simpler and more convenient.

Public facilities: Curtain wall brackets also play an important role in public facilities such as libraries, museums, exhibition halls, etc. Their stability and aesthetics provide a good environment support for these places, allowing visitors to appreciate and experience exhibits and documents more comfortably.

Design and manufacturing process of Curtain Wall Bracket

1. Design stage

Requirement analysis: At the beginning of the design, a comprehensive demand analysis of the curtain wall system is required, which includes understanding the type of curtain wall system, panel material, size, weight and installation environment. Based on this information, the designer can preliminarily determine the load-bearing capacity, structural form and connection method of the Curtain Wall Bracket.

Structural design: After clarifying the requirements, the designer will start the structural design of the Curtain Wall Bracket. This includes the shape, size, material selection, connection method, etc. of the bracket. When designing, factors such as the load-bearing capacity, stability and installation convenience of the bracket must be fully considered. At the same time, attention should also be paid to the connection method between the bracket and the curtain wall panel and the main structure to ensure that the connection is firm and reliable.

Detail optimization: After the structural design is completed, the designer also needs to optimize the details of the bracket. This includes the hole layout of the bracket, the setting of welding points, anti-corrosion treatment and other aspects. The optimization of details can not only improve the performance of the bracket, but also improve the aesthetics of the entire curtain wall system.

Drawing and review: After completing the design, the designer will draw detailed construction drawings and submit them to the relevant departments for review. During the review process, the load-bearing capacity, structural rationality, connection method, etc. of the bracket need to be comprehensively checked to ensure that the design meets relevant standards and specifications.

2. Manufacturing stage

Material preparation: During the manufacturing process, the required materials need to be prepared, and according to the design requirements, suitable materials need to be selected for cutting, forming and other processing. Commonly used materials include stainless steel, aluminum alloy, etc., which have high strength and corrosion resistance.

Processing and forming: According to the construction drawings, the corresponding processing equipment is used to cut, punch, bend and other processes on the materials to form the basic shape of the bracket. During the processing, the dimensional accuracy and surface quality need to be strictly controlled to ensure that the bracket meets the design requirements.

Welding and assembly: For the bracket parts that need to be welded, appropriate welding processes need to be used for welding. After welding, the welds need to be polished and polished to improve their appearance quality and corrosion resistance, and the various components need to be assembled to form a complete Curtain Wall Bracket.

Quality inspection: After manufacturing, the Curtain Wall Bracket needs to be quality inspected. This includes dimensional inspection, load-bearing capacity test, anti-corrosion performance test and other aspects. Only brackets that have passed strict inspection can enter the next process or be delivered for use.

Packaging and delivery: After completing the quality inspection, the qualified Curtain Wall Bracket will be packaged to prevent damage during transportation. The product name, model, quantity and other information must also be marked on the packaging and prepared for delivery.