Manufacturing process of Phoenix Tail Curtain Bracket

Phoenix Tail Curtain Bracket is a unique and exquisite home decoration. It not only carries the function of hanging curtains, but also adds a strong artistic atmosphere to the interior space with its unique phoenix tail design element.

1. Design conception

The manufacturing of metal Phoenix Tail Curtain Bracket begins with the designer's ingenious conception. The designer incorporates the graceful curves and gorgeous colors of the phoenix tail into the design, and concretizes this inspiration through hand-drawing or computer-aided design software to form a preliminary design plan. During the design process, the designer will fully consider the load-bearing capacity, structural stability and aesthetic effect of the bracket to ensure that the final product is both practical and beautiful.

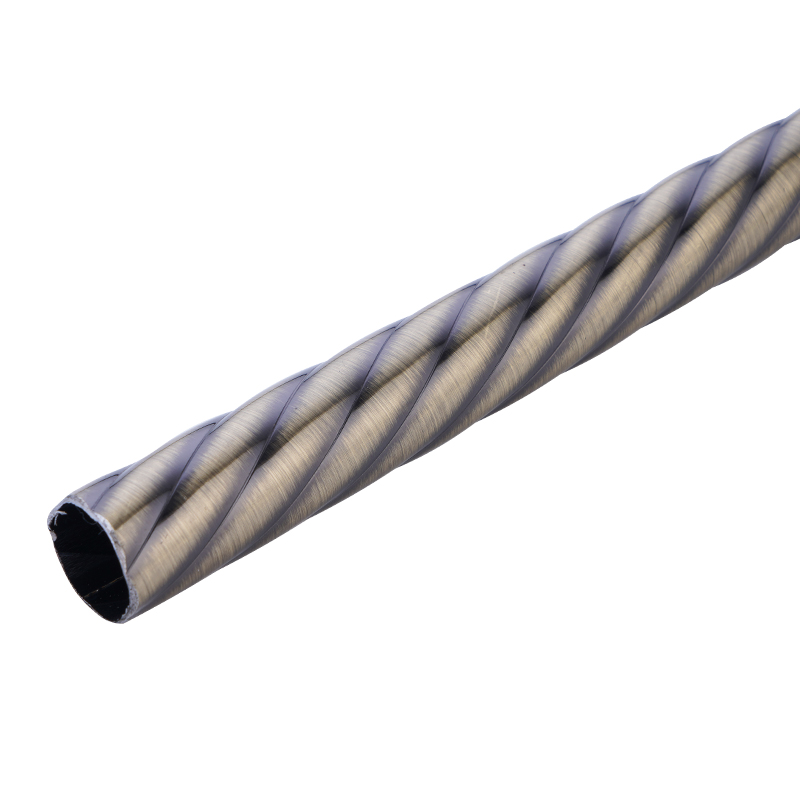

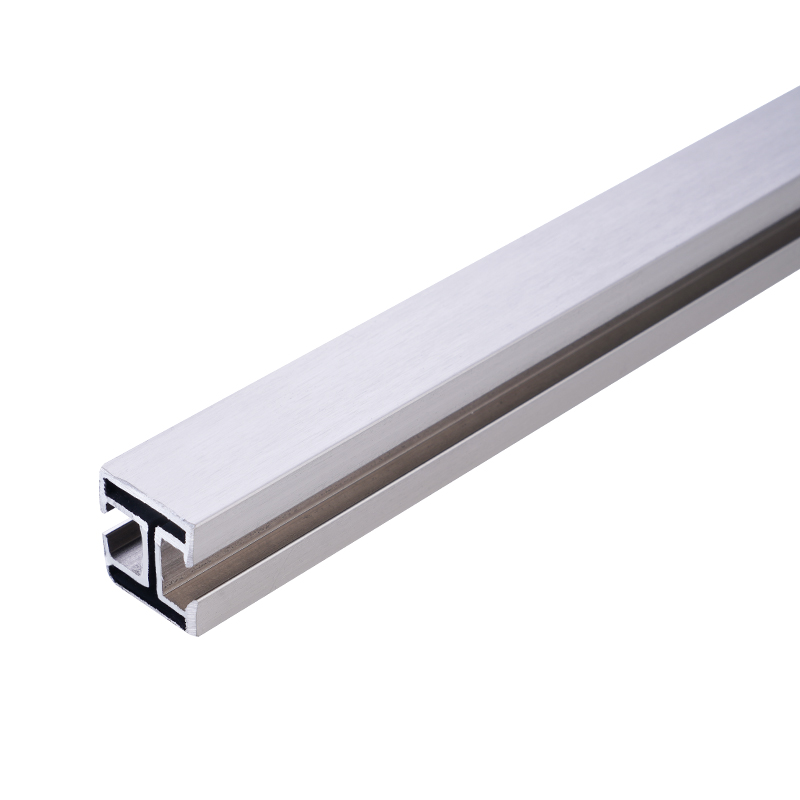

2. Material selection

The material selection of metal Phoenix Tail Curtain Bracket is crucial. High-quality materials can ensure the durability and beauty of the bracket. Usually, manufacturers choose corrosion-resistant and high-strength metal materials such as stainless steel and aluminum alloy as raw materials. These materials not only have good physical properties, but also can present different textures and colors through surface treatment processes.

3. Mold making

After determining the design plan and materials, the manufacturer needs to make the corresponding mold. The mold is an indispensable tool in the manufacturing process, which can ensure that the size and shape of each bracket are consistent. The production of the mold requires precise machining and debugging to ensure its accuracy and stability.

4. Casting and Forging

In the manufacturing process of the metal Phoenix Tail Curtain Bracket, casting and forging are key links. Casting is to pour the molten metal into the mold and wait for it to cool and solidify to form the blank of the bracket. Forging is to heat and hammer the blank to form a more complex shape and finer texture. Both links require experienced workers to operate to ensure the quality and appearance of the bracket.

5. Grinding and Polishing

After casting and forging, there will be some burrs and uneven places on the surface of the bracket. In order to eliminate these defects, the manufacturer will use grinding and polishing processes to surface treat the bracket. Grinding can remove burrs and bumps on the surface of the bracket, while polishing can make the surface of the bracket smoother and more delicate. Both steps require the use of professional equipment and tools to ensure the surface quality of the bracket.

6. Spraying and coloring

In order to make the metal Phoenix Tail Curtain Bracket have a better decorative effect, the manufacturer will spray and color it. Spraying is to apply one or more layers of paint on the surface of the bracket to increase its corrosion resistance, wear resistance and aesthetics. Coloring is to apply different colors or patterns on the surface of the bracket according to the design requirements to make it more in line with the interior decoration style. These paints and pigments need to undergo strict quality inspections to ensure their safety and environmental protection.

7. Assembly and quality inspection

Assemble the various components together to form a complete Phoenix Tail Curtain Bracket. During the assembly process, workers need to ensure that each component is installed in place and fastened firmly. After the assembly is completed, the bracket will also undergo strict quality inspections, including size inspection, load-bearing test, appearance inspection and other aspects to ensure that it meets the design requirements and quality standards.

Advantages of Phoenix Tail Curtain Bracket

1. Unique Phoenix Tail Shape

The design of Phoenix Tail Curtain Bracket is inspired by the Phoenix Tail in traditional Chinese culture. The Phoenix Tail, with its unique shape and beautiful feathers, symbolizes auspiciousness, harmony and beauty. This shape not only adds a strong cultural atmosphere to the home space, but also makes the hanging of curtains more elegant and noble. The shape of the Phoenix Tail also conforms to the modern aesthetic trend and can be integrated with various home styles, adding a unique charm to the home space.

2. Strong load-bearing capacity

Phoenix Tail Curtain Bracket is made of high-strength materials and has excellent load-bearing capacity. Whether it is heavy curtain fabrics or light gauze curtains, it can be easily handled. This strong load-bearing capacity ensures the stable hanging of the curtains and avoids deformation or damage caused by long-term use. The strong load-bearing capacity also enables Phoenix Tail Curtain Bracket to adapt to various home environments and meet the needs of different users.

3. Flexible installation method

Phoenix Tail Curtain Bracket adopts a flexible installation method and can be easily fixed on the wall, window frame or ceiling. Users can choose the appropriate installation location according to the specific situation of the home space and their own preferences. This flexible installation method not only provides users with more choices, but also makes the hanging of curtains more flexible and convenient. Phoenix Tail Curtain Bracket is also equipped with detailed installation instructions and professional installation tools, allowing users to easily complete the installation process.

4. Stable support structure

The support structure of Phoenix Tail Curtain Bracket has been carefully designed and has excellent stability and durability. The connection between the bracket and the wall or window frame is fixed with high-strength screws to ensure that the bracket will not loosen or shake. The bottom of the bracket is also equipped with an anti-slip pad to effectively prevent noise and scratches caused by friction. This stable support structure not only ensures the stable hanging of the curtain, but also provides users with a more comfortable and quiet home environment.

5. Easy to clean and maintain

The surface of Phoenix Tail Curtain Bracket has been specially treated to be dust-proof, anti-fouling and easy to clean. Even after long-term use, it will not accumulate excessive dust or stains. Users only need to wipe it gently with a damp cloth to restore the luster and beauty of the bracket. The material of Phoenix Tail Curtain Bracket also has certain anti-corrosion properties, which can resist the influence of adverse factors such as moisture and corrosion, and prolong its service life.