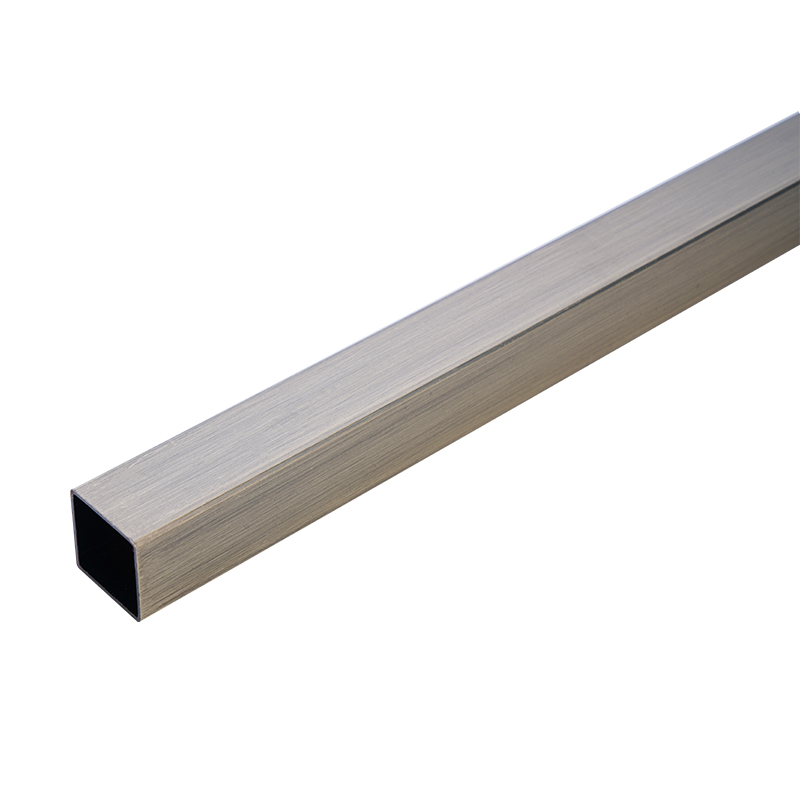

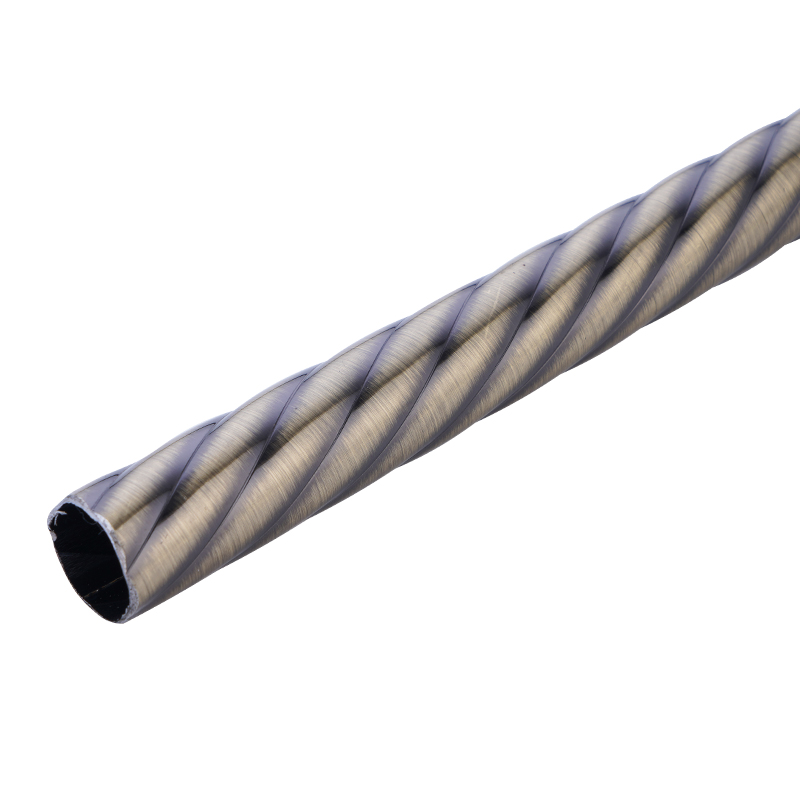

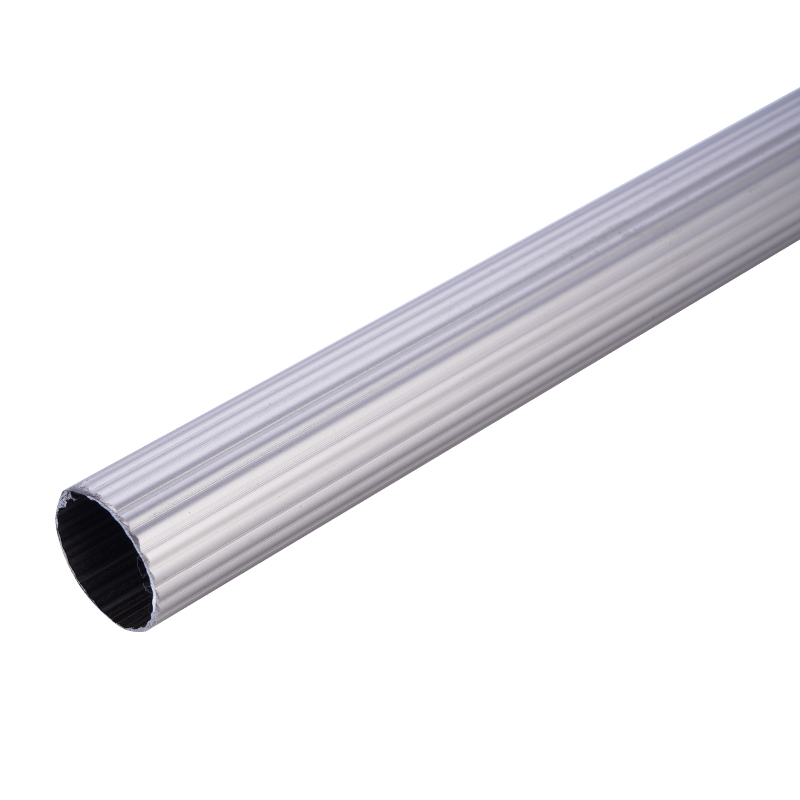

To ensure that curtain tracks do not deform or bend during long-term use, it is necessary to comprehensively consider various aspects such as material selection, installation methods, load management, and regular maintenance. When selecting tracks, choose materials with high strength and high durability, such as aluminum alloy or stainless steel. These materials have high flexural strength and corrosion resistance, and can withstand long-term loads without deformation. In addition, high-quality plastic tracks also perform well in lightweight curtain applications.

During installation, ensure that the track is firm and level, and use a sufficient number of brackets or fixing points, especially when the track is long or the curtains are heavy. The spacing of the brackets should generally be controlled between 60 and 100 cm to provide sufficient support and prevent the track from sagging in the middle.

Choosing tracks with built-in reinforcements or thickened designs can increase their rigidity and reduce the possibility of deformation. Double or multi-track designs can also distribute the load, further enhancing stability. Reserve sufficient expansion and contraction space at both ends and in the middle of the track to accommodate the thermal expansion and contraction of materials caused by temperature changes, thereby preventing the track from deforming due to thermal stress. Select the appropriate track and pulley system according to the weight of the curtain to ensure that the load-bearing capacity of the track can match the weight of the curtain. Heavy curtains require reinforced tracks and brackets.

Regularly inspect the fixed points and brackets of the track to ensure they are not loose or damaged. Clean the track to keep it sliding smoothly and prevent increased resistance and unnecessary stress caused by dust or debris. Lubricate the track and pulley system properly to reduce friction and prevent local stress concentrations caused by jammed pulleys.Use appropriate lubricants and avoid lubricants that corrode the track material. In high humidity or chemically corrosive environments, choose tracks made of corrosion-resistant materials (such as stainless steel or specially coated aluminum alloy) and ensure good ventilation in the environment to reduce the risk of corrosion. Finally, avoid excessive force or speed when opening and closing curtains to avoid additional stress and wear on the track and pulley system.